LIXIL Standardizes Low-Carbon PremiAL Across Its Product Line — Eco-Friendly Aluminum Produced with 50% Less CO₂, and No Extra Cost

Expanding LIXIL's Impact by Balancing Environmental and Economic Value

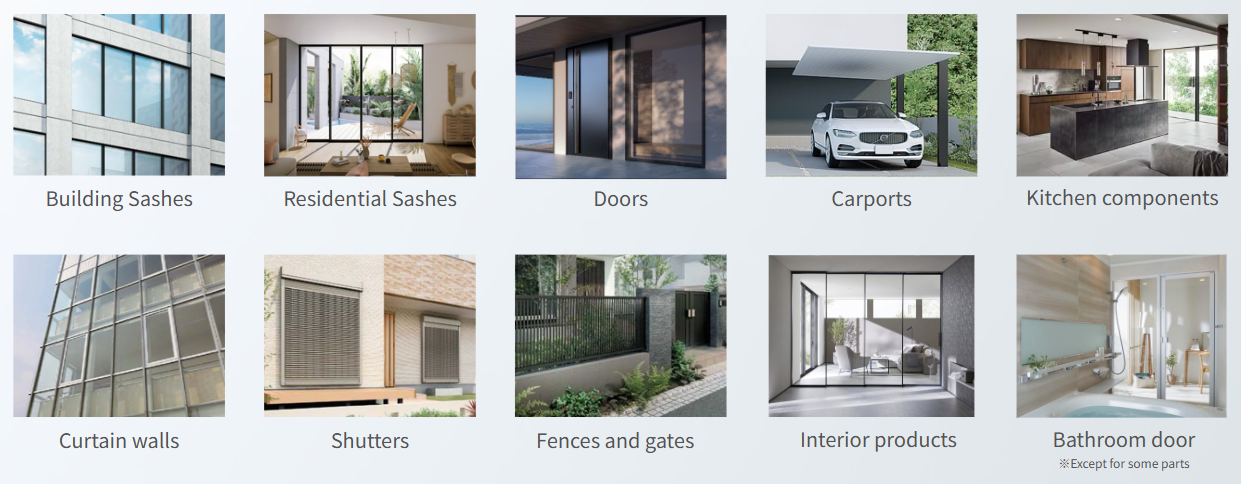

Tokyo – LIXIL Corporation (“LIXIL”, TSE Code: 5938), maker of pioneering water and housing products, will standardize the use of "PremiAL," its recycled low-carbon aluminum, across its product¹ line at no additional cost. The innovative building material reduces CO₂ emissions by approximately 50% compared to aluminum manufactured using only new ingots. PremiAL will be incorporated into all products using aluminum extrusions manufactured by LIXIL and will be rolled out starting in October 2025.

Satoshi Yoshida, Executive Officer and Executive Vice President, LIXIL Housing Technology (LHT), commented:

"At LIXIL, we are focused on creating a positive impact on the environment and society through our innovative products and services, aiming to solve social challenges while driving further business growth. LIXIL is committed to reducing the whole-life carbon of buildings in Japan, and our PremiAL” series, which leverages nearly 30 years of aluminum recycling expertise, is a key solution for significantly reducing embodied carbon. By pioneering this solution not only for commercial building materials but also for residential products, we will contribute to the continued decarbonization of the construction industry."

To achieve a decarbonized society, it is essential to reduce emissions from the building and construction sector, which accounts for 37% of global CO₂ emissions. Consequently, there is a growing focus on lowering the carbon footprint of aluminum, a material widely used not only in the construction industry but also in various other sectors such as transportation. In June 2025, the Japan Aluminium Association established a definition for green aluminum, further strengthening its commitment to low-carbon products. The key to reducing the environmental impact of aluminum products is to promote aluminum recycling, which does not use primary ingots. Aluminum’s low melting point compared to other metals allows it to be melted and recycled using minimal energy. Using recycled material instead of virgin material for aluminum products can reduce carbon emissions by 97%².

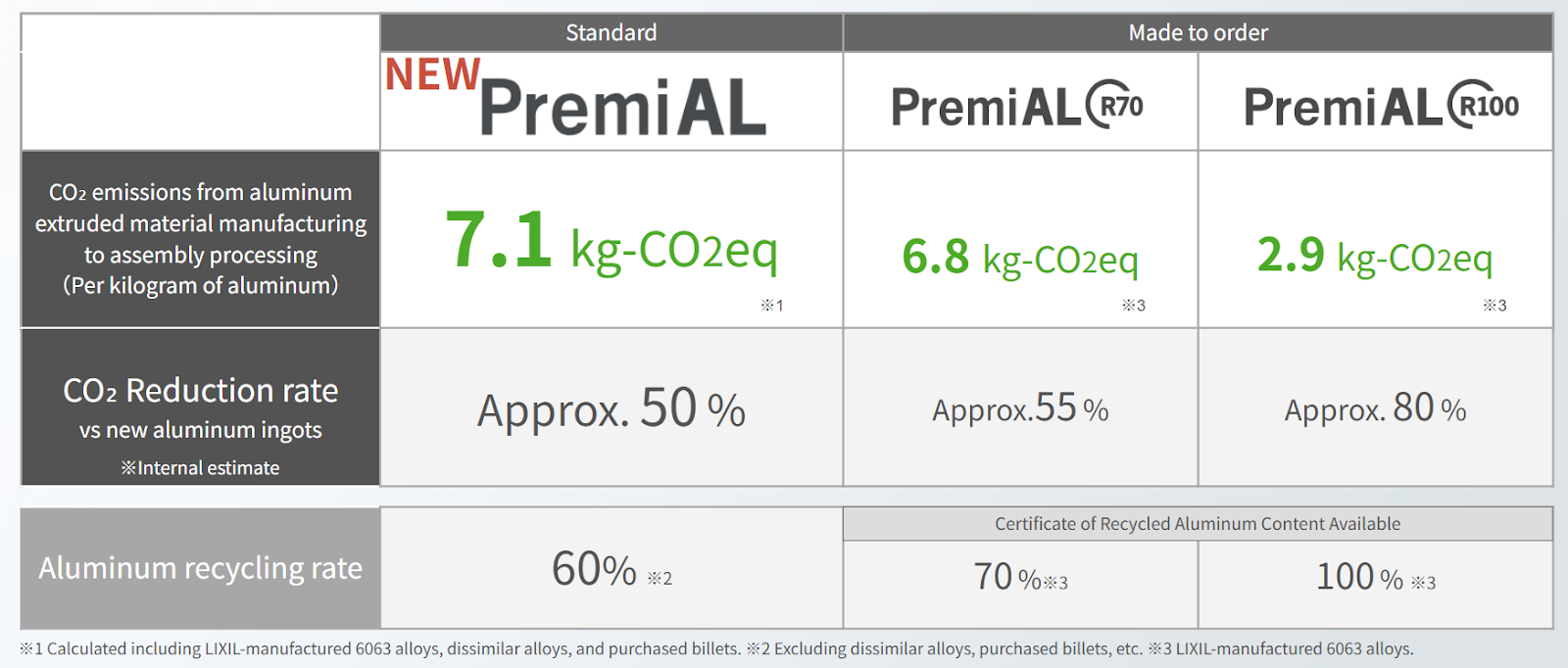

Leveraging its world-leading aluminum recycling technology, LIXIL launched "PremiAL R70" with 70% recycled aluminum content in December 2022, followed by "PremiAL R100" with 100% recycled content in October 2023. The use of these materials has been limited to select products, mainly for non-residential applications.

To further expand the impact of the "PremiAL" series, LIXIL will now extend the availability of "PremiAL" recycled low-carbon aluminum, which reduces CO₂ emissions by approximately 50% compared to manufacturing using only new aluminum ingots, from a limited range to all products using LIXIL-manufactured aluminum extrusions, including those for residential and exterior applications.

In the fiscal year ending March 2025, while LIXIL's average recycled aluminum content reached 80%³, there was variability in the recycled aluminum usage rates for non- “PremiAL” series aluminum extrusions. To address this, innovations in production technology and improved management methods have enabled LIXIL to standardize the recycled aluminum content for each lot and raise the minimum guaranteed level to at least 60%³. This allows to expand the offering of “PremiAL” to all products that use LIXIL’s aluminum extrusions, regardless of the product or production lot. Furthermore, "PremiAL" can be mass-produced at all five of LIXIL's domestic and international aluminum manufacturing plants⁴, making it possible to offer products with high environmental value at the same price as conventional ones.

LIXIL has also obtained third-party "SuMPO EPD" verification⁵ for all its manufactured aluminum extrusions, which was publicly disclosed on September 17. The CO₂ emissions per 1 kg of aluminum for LIXIL aluminum extrusions, from manufacturing to assembly and processing, amount to 7.1 kg-CO₂eq. Compared to aluminum extrusions manufactured using only new ingots, this achieves a reduction in CO₂ emissions of approximately 50%.

Under its Environmental Vision 2050, LIXIL aims to achieve "Zero Carbon and Circular Living." One of the key focus areas is "Promoting the Circular Use of Resources," with a goal to increase its recycled aluminum usage to 100% by the fiscal year ending March 2031. The expansion of the "PremiAL" offering will further accelerate efforts toward achieving this target.

LIXIL believes that its efforts to address the needs of the environment, society, and people today and in the future are integral to sustainable business growth. LIXIL will continue to develop products and services that create a positive impact on daily life and society in a rapidly changing world.

1 LIXIL-manufactured aluminum extrusions only.

2 The process of extracting aluminum as a metal from resources. This differs from CO2 emissions during PremiAL manufacturing.

3 Based on in-house manufactured billets (6063 alloy). Excludes purchased billets and some different alloys.

4 As of September 2025, at factories in Thailand, Vietnam, Oyabe, Shimotsuma, and Ariake.

5 Source: https://ecoleaf-label.jp/

<Reference Material>

■”PremiAL” series, recycled low-carbon aluminum

PremiAL, which reduces CO₂ emissions by approximately 50% compared to aluminum extrusions using new ingots, is now applied to all LIXIL aluminum products*. PremiAL R70 and PremiAL R100 will continue to be available as made-to-order products as before.

*Applies only to aluminum extrusions manufactured by LIXIL.